Our service range

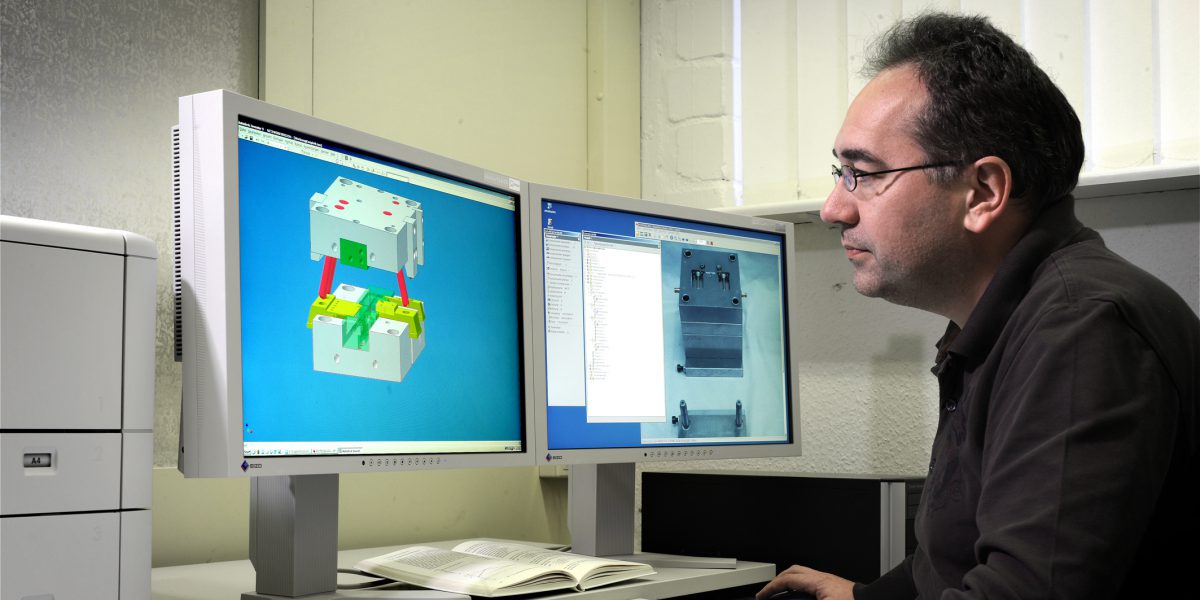

- new construction of tools and moulds in the fields of both, injection moulded components for mass consumption, industry and engineering as well as thin-wall technology

- state-of-the-art moulds from samples and small batch tools to high-performance injection moulding dies ready for series production

- application of hot runner systems and selective lasermelting technology

- production of components for businesses of tool design and injection moulding following individual CAD and/or 2D data

- broad service within the scope of cyclical tool maintenance according to customized specifications as well as anti-cyclically, depending on the application and state of the mould

- quick and reliable die area modifications for design and/or technical reasons

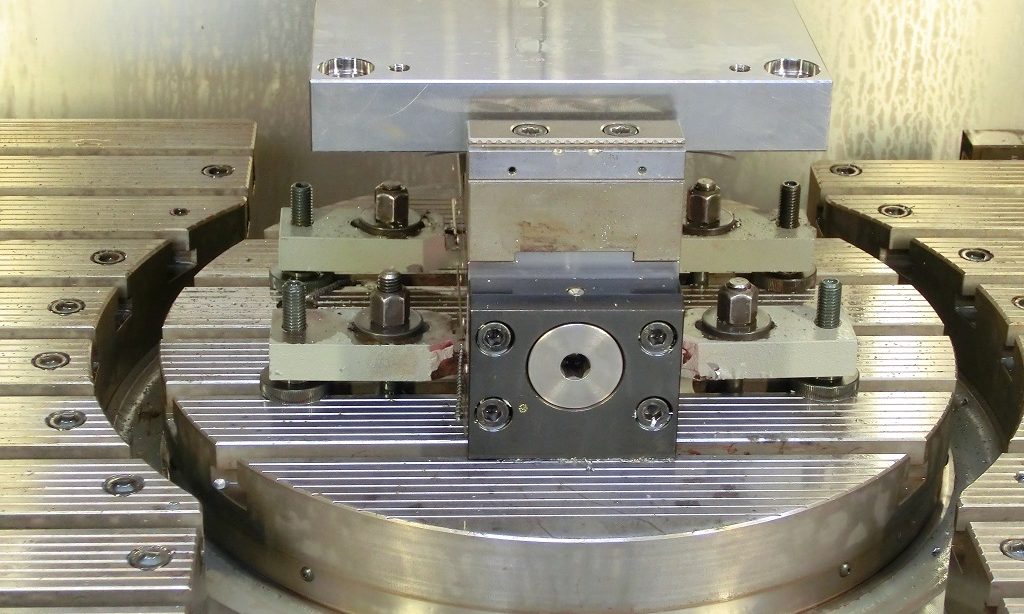

- high-precision and special component manufacturing within the scope of our core competencies of milling, cavity sinking and erosive cutting

- upgrading and finishing by both, flow and vibratory grinding as well as sand blasting technology

- reliable spare part supply in the field of injection moulding

- adherence to schedules and delivery dates

- professional storage of non-active tools and moulds including logistic support

- certified quality and environmental management system following DIN EN ISO 9001:2008 respectively DIN EN ISO 14001:2009

Benefit from our first-class quality and our outstanding price-performance ration.

We look forward to receiving your enquiry and shall be glad to submit our individual offer.